PPC119 | TECHNICAL

Pest management consultant Tom Holmes has spent much of his career developing insect light traps (ILTs), providing training on how they work, and crucially, how to use them. In this PPC article, Tom shares his extensive knowledge to help pest professionals better understand these vital tools.

What are ILTs for? Firstly, let’s start at the top. What do we, as professionals within the pest management industry, do? I argue that we help maintain public health, reducing the risk of disease, damage and distress for our customers and theirs.

How do we do that? We use our experience and knowledge to solve problems, with appropriate tools to help us along the way. And that’s all ILTs are: they’re tools to help us maintain public health.But they can be used in different ways, and that’s what we’ll explore here.

I’m going to make the case that there are three fundamental ways in which to use ILTs:

- For control

- To monitor

- For population suppression.

Let’s explore each in a little more detail.

Control

Firstly, what do we mean by ‘control’, within the context of flying insects? We’d probably all describe it differently, but for now, I’m going with “Remove all flying insect pests from a given environment”. And ILTs can absolutely be used in this way. For example, in regions where the climate is always going to support large numbers of flying insects (South East Asia, the Middle East, North Africa, etc), ILTs can, and are, used to help remove all insects from a space.

Closer to home, non-sensitive applications (such as non-food-based warehousing) can benefit from ILTs to remove flying insects from that space. In these environments, electric killing grid models are often used, where the impact of ‘zapping’ the insect has minimal public health implications. This style of ILTs can also require less effort to maintain, with emptying the catch tray and a quick wipe down, all that is needed to keep them running.

Finally, seasonal pests sometimes call for dedicated solutions. Take cluster flies for example. In Autumn, as the last days of summer disappear, they take refuge in loft spaces and similar environments, and can congregate in huge numbers - hundreds, if not thousands. In this scenario, I’d recommend a specialist ILT, typically an electric killing grid model with a larger catch tray, of which there are several available on the market.

Here again, we’re trying to ‘control’ the infestation (to eradicate it), albeit typically over a limited period of time.

Where we want to “control”, what do we need to consider? Well, we need the right tool for the job. I’ve already talked about dedicated ILTs for cluster flies, but in a large warehouse facility, we’ll likely need a large unit, and the right number to manage the space (don’t get me started on so-called ‘coverage areas’ of ILT models - that’s something for another day!).

Similarly, are they positioned appropriately to be effective and simple to service? And whilst we’ve made that call to use them as ‘control’, it’s always worth regular reviews of the environment and results, to see whether the dynamics (and required action) have changed.

"Monitoring with ILTs helps track insect activity and guides when action is needed."

Monitor

Monitoring is a cornerstone of an integrated pest management approach to maintaining public health. Much is made of this, and at times it can be overthought.

Put crudely, if there is no pest activity right now, we should keep reviewing to see if the situation changes. If it does, let’s take appropriate action. This gives me my definition of ‘Monitor’ within our context of ILTs as “Review changes in insect activity, before taking action where needed”.

Using ILTs to monitor is a big subject, and could quite easily justify a dedicated exploration on its own. However, as an overview, where might we want to monitor? To put it crudely again, wherever and whenever, there is a high-sensitivity activity. Typically, (but not exclusively), this is where food production or processing - food and beverage (F&B) establishments, high-end hospitality, and nutritional or pharmaceutical facilities are located. Within all of these environments, any change in flying insect activity matters. How do we know if there’s been a change? We monitor.

Those who’ve been in the game a while will remember the term “catch tray analysis”—a simple concept that was hugely problematic in reality. The idea was that technicians could analyse the quantity and species of insects caught by reviewing the contents of a catch tray within an electric killing grid ILT (anyone know which insect this wing belongs to?).

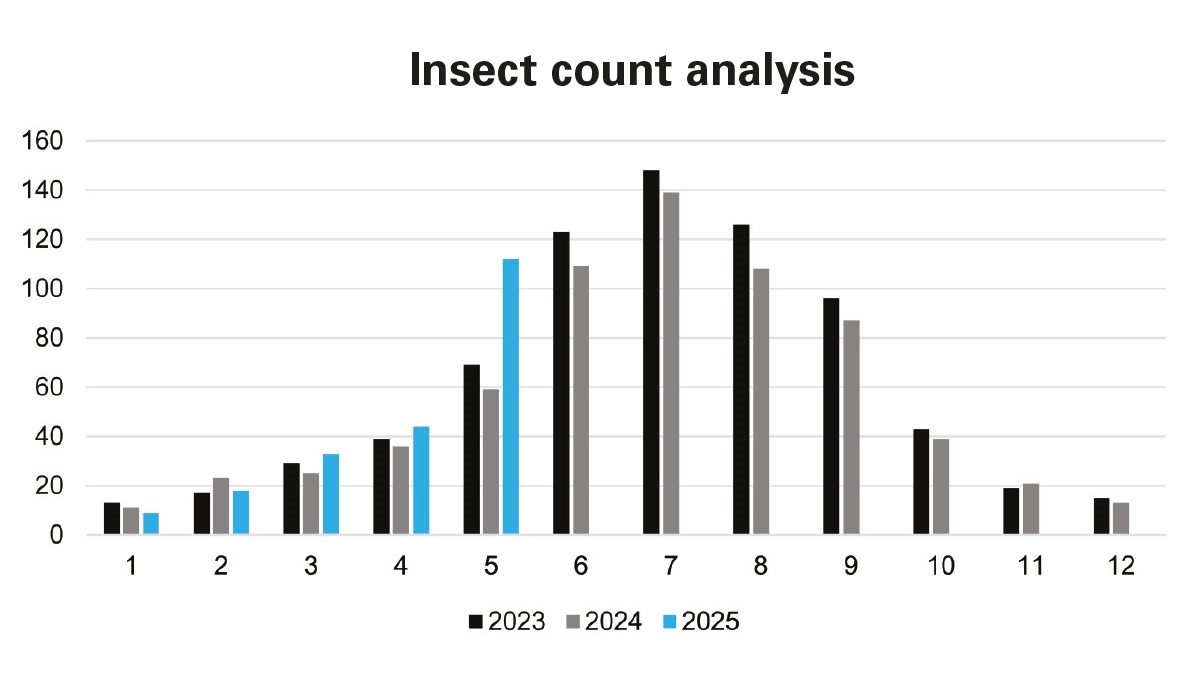

Thankfully, with the widespread adoption of glueboard technology ILTs across Europe in the early 1990s, our lives became much easier. By recording the number of insects caught upon a glueboard at regular intervals, we can assess whether the insect population is declining, increasing, or remaining stable. We can do this from service to service or by comparing it to the same period in previous years. Throw the captured data into a simple bar chart, and we have a hugely powerful, visual picture of flying insect activity on site. In short, we’re monitoring.

What do we need to consider when we’re monitoring? We start, of course, with IPM. To monitor flying insects with ILTs we need data. Typically, this means having installed the ILT in an appropriate position, we return at regular intervals (monthly, quarterly, possibly even weekly), to collect the agreed catch data.

What data? Possibly we go all the way to insect species identification, or perhaps a split between ‘large fly’ and ‘small fly’ (to help us identify between pests originating inside, or those entering the facility from the outside), but as a base level, we will certainly require ‘a count’.

Comparing insect catch count data across fixed periods is the beating heart of using ILTs for monitoring. Again, catch analysis warrants its own detailed discussion, we also consider:

- How comparing data against the same period from previous years helps combat the impact of seasonality

- Variations in ‘how to count’ - a full count, a representative count of the glueboard, (eg, count a quarter and multiply by four), or as is more than common that you’d imagine, a visual guess.

- How the recent emergence of remote monitoring technology might help with some of these challenges, along with many others.

However, we’ll save these thoughts for another day.

Population suppression

The third scenario is an application where flying insects will always be present, but we can use ILTs to help keep the population stable. Think waste management facilities, water treatment sites, etc. We’ll never be able to completely remove (to control) the insects, but ILTs can help suppress the population to manageable levels. My definition of this use? “Keep ongoing insect populations in check”.

What do we need to consider in these scenarios? We’re almost certainly going to need large units with significant capacity. If you’re selecting a glueboard model, it will need a large glueboard, but a large electric killing grid model might be a better bet in these locations. Either way, the units will require regular servicing to ensure the glueboard or catch tray isn’t full and the ILTs remain in working order to attract and catch insects.

With these three uses explained, let’s revisit our central question: What are ILTs for? Well, all three uses are entirely valid. However, what is really important is that you are clear which reason you are using them. If we’re using an ILT for monitoring, we will interact with it very differently than if we’re using it for population suppression.

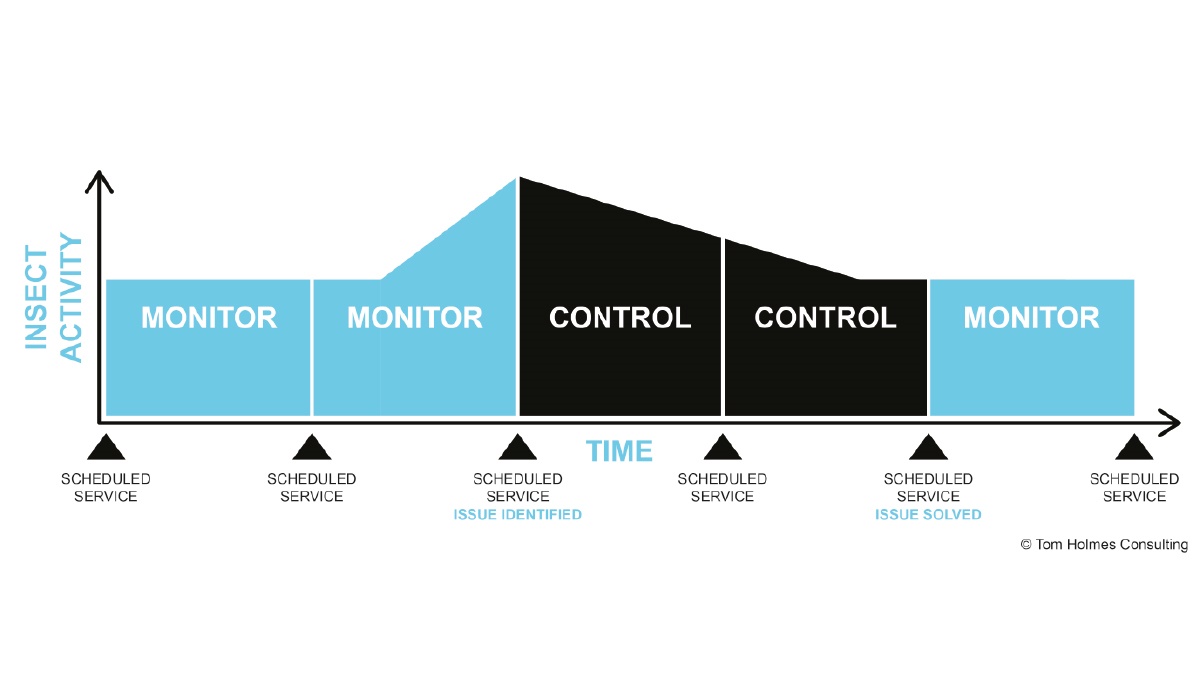

That said, the particular use can change over time. For example, an ILT used as a monitoring tool can support control activity once an infestation has been identified, before returning to an

ongoing monitoring tool once the problem has been managed. But here’s the twist in the tale.

There’s a fourth. And it’s an uncomfortable one - Compliance.

"Make sure you are clear about why you are using it."

As pest management professionals, it’s a slightly sordid reality that in low sensitivity applications (high street stores, takeaways, butchers, bakers, etc), more often than not, they just want a tick in the box for their health inspector. And throwing a cheap and nasty zapper on the wall may well do that for them – make them compliant.

There are some impactful considerations for us to manage in this scenario. If the ILT has been sourced elsewhere (quite possibly a low-cost, electric killing grid unit), what are the fly catch efficacy expectations of the end user? If we are to service it, what are the consumables (UV lamps and glueboards), and can we source them? How easy is the ILT to service and maintain?

If it’s a low cost electric killing grid unit, it may not be designed with serviceability in mind, so what does that mean for how long it will take us to service (who else has had the pleasure of attempting to service a unit that requires you to release screws to get inside it, dropping the screws, then spending ten minutes searching for them on the floor?). This can seriously impact the profitability of that contract.

A low-cost unit might seem appealing, but what about sustainability? Will it last, can it be recycled, or is it headed for landfill? We should aim to do better in this regard.

In summary

Control, monitor, population suppression and compliance; four uses of ILTs. All are valid and catered for by the vast array of models on the market. And there is no right or wrong use of the four. But, make sure you are clear about why you are using it. Because, as we’ve discussed, that impacts which model you select, and how you use it, as a tool to help you maintain public health for your client, whilst delivering profit for yourself.

Online CPD

An online CPD quiz based on this feature is now available on the BPCA website. BPCA Registered members and anyone with a MyBPCA account can take a CPD quiz at any time bpca.org.uk/find-cpd or sign up at bpca.org.uk/mybpca