PPC120 | TECHNICAL

Richard Faulkner, Envu’s National Account and Technical Manager for the UK and Ireland, gives PPC readers an overview of the Stored Product Insects (SPIs) that UK pest professionals are most likely to encounter.

For as long as I can remember, I have been fascinated with insects. They are amazing and unbelievably complex creatures.

We should never dismiss or ignore these tiny organisms that play such an important role in our environment, ecosystems and day-to-day lives.

In these next few paragraphs I will give a little bit of insight into the more common SPIs that we come across in the UK, taking a brief look at their biology, their impact and how they can be treated.

What are Stored Product Insects (SPIs)?

SPIs are a group of insects that infest and damage stored food products, including grains, processed foods, and even tobacco.

They get introduced into your customer’s stores, factories, and homes via commodities. As a result, SPIs cause significant problems across the whole food chain, from farm to fork; in raw material storage, processing, retail environments and domestic properties.

Most SPIs originate from tropical or semi-tropical climates where they infest dried plant-based materials. Where do we find them?

- Raw material storage

- Grain silos, farms, feed mills, grain collectors

- Ports and harbours

- Transport

- Ships, containers, vehicles and trailers

- Processing

- Mills, bakeries, food processing plants

- Feed mills and stores/warehousing

- End users

- Shops, supermarkets and private households.

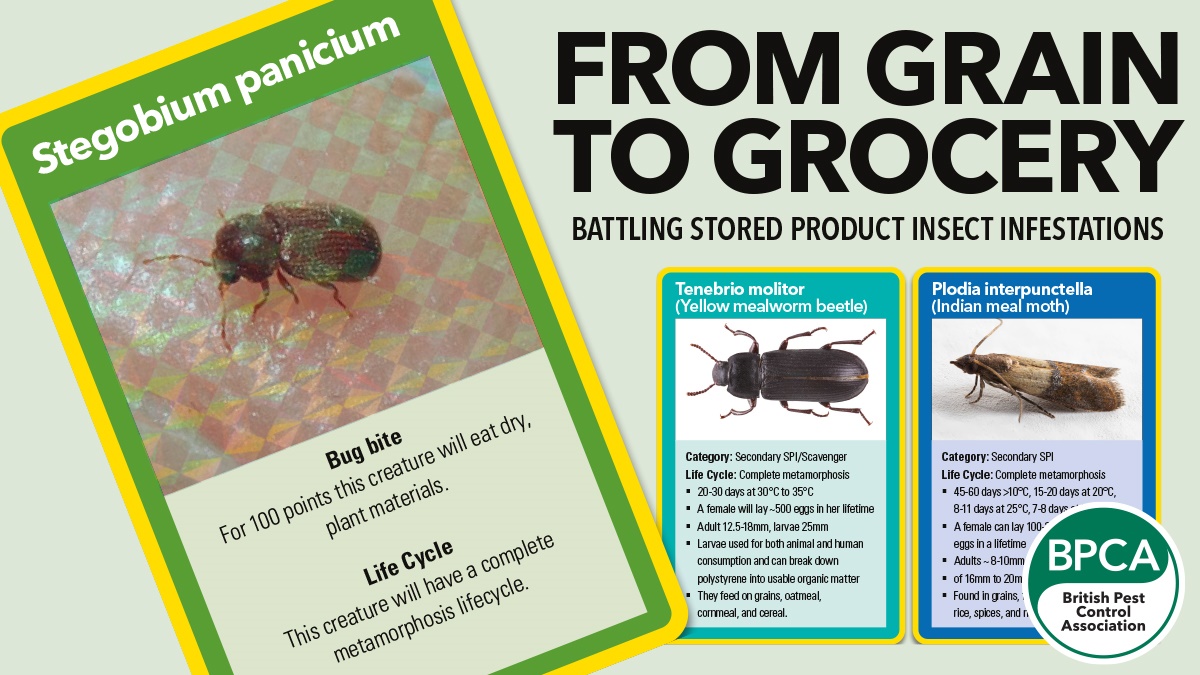

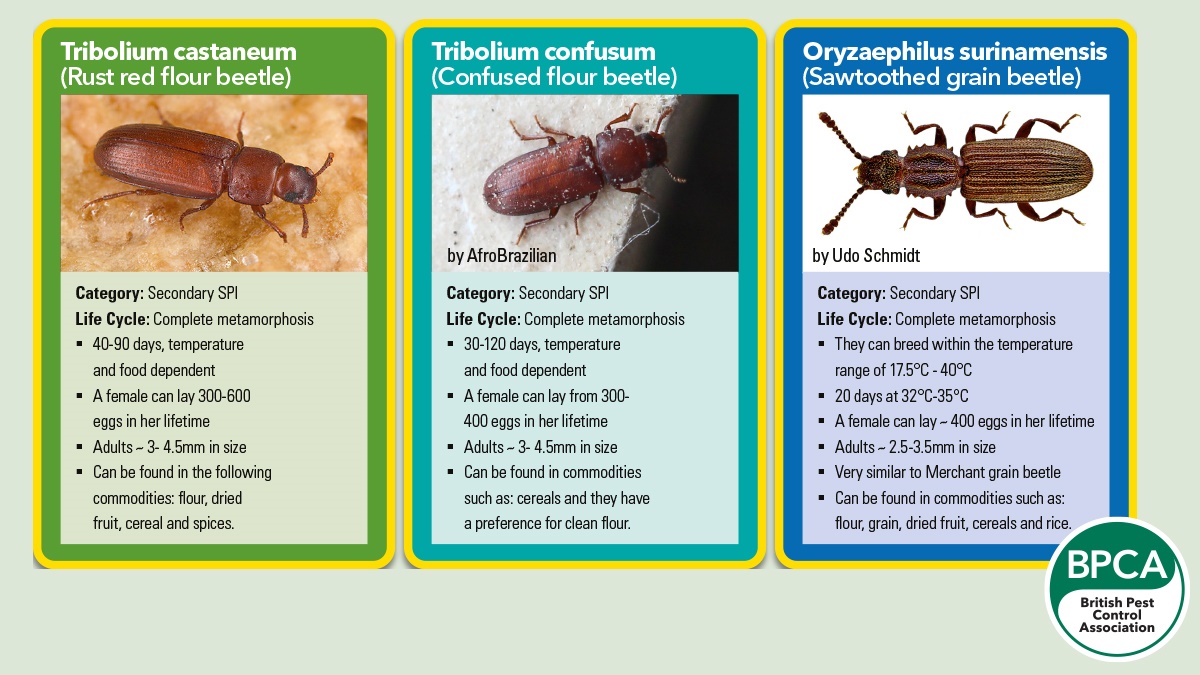

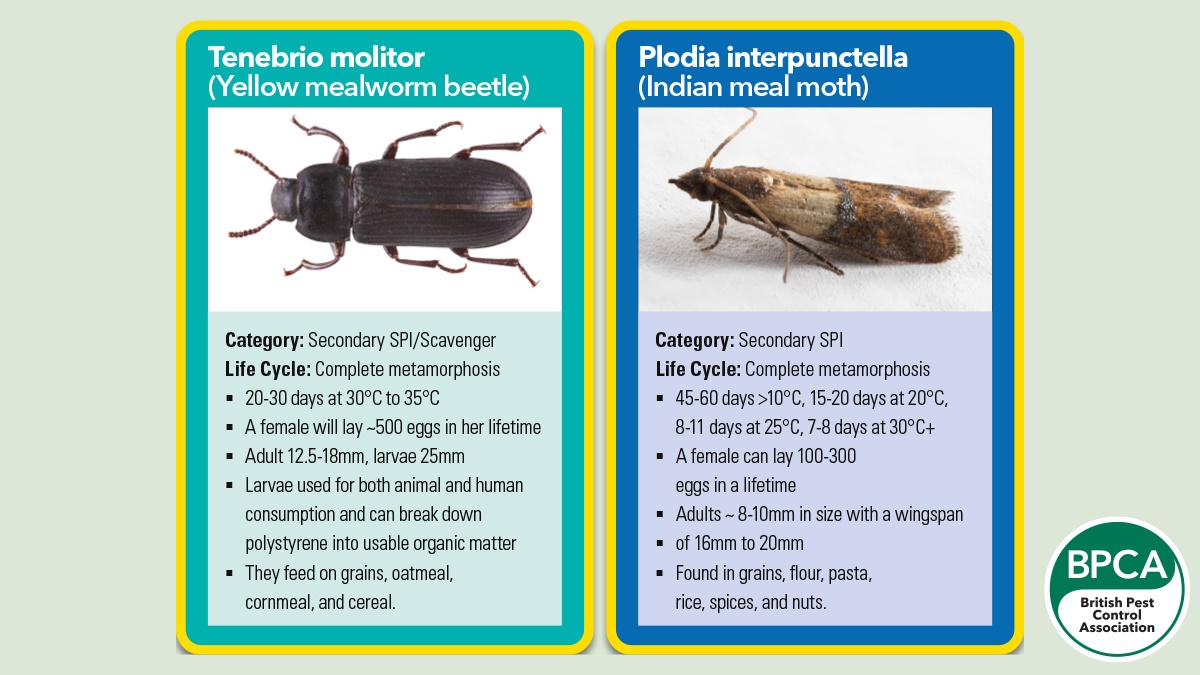

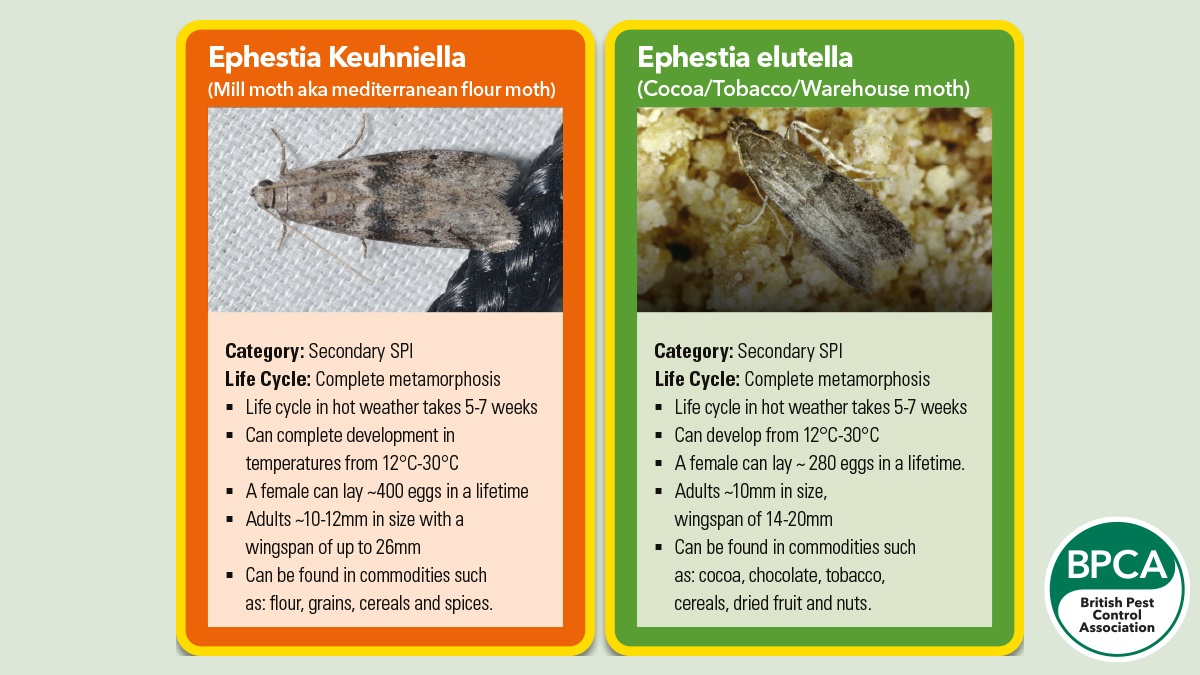

Categorising Stored Product Insects

SPIs can be divided into two categories; Primary and Secondary. Primary SPIs are insects capable of attacking and damaging whole, intact grains, such as the Rice Weevil.

Secondary SPIs, however, need the grain to be broken, processed, or damaged before infestation can occur. Examples include Indian Meal Moths and Merchant Grain Beetles, both commonly found in stored food products.

Stored Product Beetle and Moth Life Cycles

Like all other beetles and moths, SPIs exhibit ‘Complete Metamorphosis’. Egg - Larvae - Pupae - Adult

The larval stage is the growth stage; this is the stage that does the most feeding and therefore causes the most damage and loss of commodity.

The Adult stage is the reproductive stage of the life cycle. As the majority of the life cycle takes place in the food commodity, this can cause a number of issues with the infested product such as:

- Direct feeding

- Contamination with bodies, body parts, faeces, webbing and frass

- Promotion of mould growth

- Grain germination

- Discolouration of products, especially flour

- Taint (Unpleasant flavour).

All of this can have a major economic impact, reduction in yield, downgrading of product, spoilage, product rejection, fines from authorities, damage to production machinery, recall and destruction of product.

SPIs are said to be the world’s most expensive pest.

Integrated Pest Management (IPM)

An IPM approach is fundamental when dealing with stored product insects. Deep cleaning at high levels and in dead spaces in production machinery, service voids, drains and the fabric of the building needs to be meticulous.

This will remove breeding sites and, when dealing with active infestations, will remove at least 75% of the problem. This will make your job easier as you will only have to treat the remaining adult insects.

Treatment of grain stores

Grain stores should be thoroughly cleaned before new grain is introduced.

Firstly the store should be deep cleaned, removing any old product and debris that could be harbouring or providing breeding sites for SPIs.The internal structure (fabric) of the store must then be treated with a specially formulated residual insecticide.

To optimise efficacy this should be carried out as close to two months before the newly harvested grain is introduced into the storage area. This allows the insecticide to knock down and kill the resident SPI population, giving the new grain optimum protection on its arrival.

The store needs to be well-ventilated, dry and properly sealed. The newly harvested grain should then be loaded into the store using a conveyor. As the grain travels on the conveyor it is treated via a sprayer system that coats the grain with another specially formulated insecticide, which will provide optimum protection for the grain for up to 12 months.

Insecticidal treatments

Spray treatments

When dealing with SPI infestations, spray treatments can be very effective. Especially when dealing with localised infestations or immediately after cleaning has taken place.

Crack and crevice treatment

Taking the insecticide to the insect in harbourage.

. 1 Barr pressure

. Pin Stream Nozzle.

Band treatment

Putting a residual insecticide on a surface so the insects land and travel across it.

. 2 Barr pressure

. Fan Nozzle.

Cold fogging (misting/ULV)

This space treatment is most effective for knocking down adult flying insects in open areas.

Cold Fogging machines use high pressure to turn the insecticide into tiny particles that are dispersed into the air.

Size = 5 to 30 microns.

Thermal fogging

This space treatment is particularly effective for rapidly knocking down adult flying insects. Thermal fogging can quickly fill large-capacity areas, ensuring the insecticide reaches all parts of the space.

The heat used in the process converts the insecticide into fine particles that are then dispersed throughout the air, targeting insects wherever they are.

Thermal foggers generally produce smaller particles (droplets) than cold foggers.

Size = 0.5 to 10 microns

Fumigation

Fumigation can be used to treat whole buildings, machinery, containers and commodities.

Fumigants kill all life stages of the insect. They are extremely toxic and therefore dangerous, which is why fumigation can only be carried out by fully trained Fumigators.

Once the treatment is completed and the area properly vented, then there is no residual chemical left on site. Common fumigants used in the UK are:

- Aluminium Phosphide

- Sulfuryl Fluoride.

Controlled Atmosphere Treatment (CAT)

CATs are used to treat high value items such as artwork and museum pieces for the control of insects.

Food items such as coffee or any raw commodity that is classed as organic can also potentially be treated this way.

The main gases used for CAT treatments are Carbon Dioxide and Nitrogen. The regulated concentrations of inert gases are used to replace the extracted air. This treatment is slow but environmentally friendly. It leaves no residues after treatment.

Heat treatment

Heat Treatment kills all life stages of the insect. These work by heating the environment to over 50°C. At this temperature proteins (DNA & RNA) denature and breakdown. This results in the death of all life stages of the insect.

This temperature should be held for a minimum of 30 minutes. Machinery and buildings can be treated using heat. Once the treatment is completed there is no residuality.

Mating disruption

This method is used against Plodia and Ephestia species. Devices are placed that flood the environment with sex pheromone. It masks the natural plumes of sex pheromone produced by the females.

This excites the male moths causing them to fly around trying to find a mate. They exhaust themselves and die without finding one. This needs to be carried out in conjunction with deep cleaning of machinery for the best efficacy.

This is best used as part of an Integrated Pest Management Programme and needs to be used in conjunction with high levels of cleaning, machinery inspections, monitoring and chemical treatments.

Insect monitors and insect light traps

Due to innovation and advancements in technology, traps and the way that we monitor SPIs are becoming more advanced. We have multi-species traps, species specific lures, and patented LED light technology.

Insect monitors and Light Traps are essential parts of our tool kits. They can help us pinpoint areas that need to be investigated, help us secure specimens for correct ID and allow us to set critical limits with our customers to trigger cleaning and treatment schedules.

Conclusion

The main thing when treating SPIs is to make sure that you have a correct ID. If you know your enemy, you’ll know how to break the insect’s life cycle.

Good communication with your customer is key. They need to understand the importance of cleaning, of being thorough and what they need to do in order to help you solve their SPI issues, to protect their image, brand, and ultimately, their business.

Ever since humans began storing food commodities, SPIs have posed a problem.

Over time, they have evolved and adapted alongside changes in our food manufacturing processes and storage facilities, becoming more resilient as these systems have grown larger, more sophisticated, and increasingly complex.

These tiny insects are both fascinating and challenging to treat, which is just one of the many reasons why working as a pest controller can be so rewarding – and, yes, great fun!